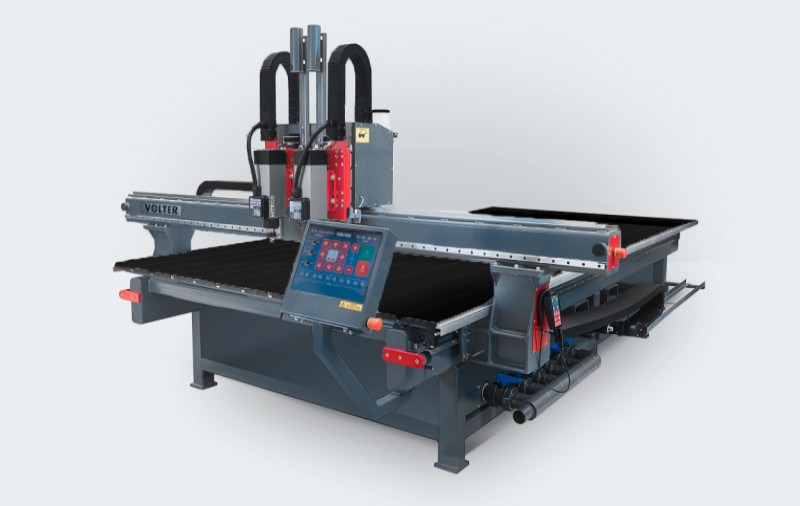

Welcome to VOLTER. We are the leading Czech manufacturer of large format professional 3-axis CNC routers for processing a wide range of materials. Our CNC machines are designed to meet the needs of industries around the globe, from Europe and America to Asia and Africa. Get in touch with us today and discover how VOLTER CNC machines can improve your production process.

Fully Customizable Solutions Configure

Configure your VOLTER CNC router

with tailored options for any

production need

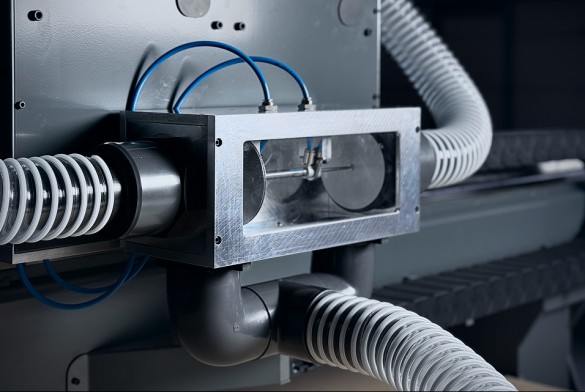

Precision You Can Trust

Achieve accurate milling, cutting, and engraving with superior versatility

Engineered for Reliability

Designed for 24/7 operation, VOLTER routers ensure consistent uptime and dependable performance

12+

Years of expertise

40+

Countries worldwide

20+

Models of CNC Routers

30+

Custom options

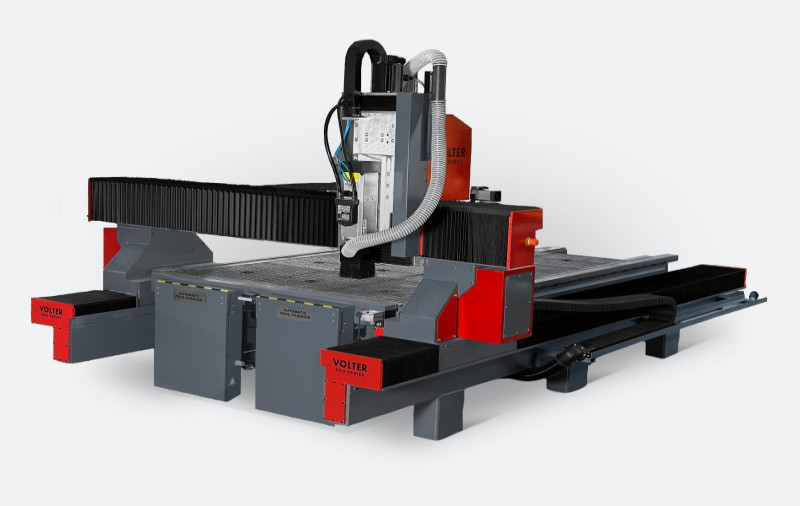

Series L

More information

- Best-selling, all-purpose CNC router

- Wide range of sizes — for full-sheet cutting

- Supports almost every feature we offer

- Balanced choice for everyday production tasks

Series SX

More information

- Compact CNC router for small-format work

- Perfect for parts, prototypes, and tight spaces

- Lower cost, same processing quality

- Ideal where space or budget is limited

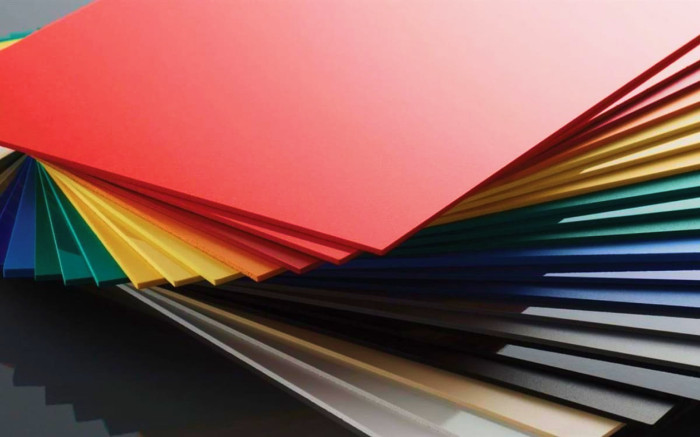

Series ACP

More information

- Dual-spindle CNC for faster panel processing

- Made for aluminium composite, HPL and facades

- Two tools work in sync — no need to switch

- A real time-saver for signage and cladding

Series PRO

More information

- Built for industrial, high-precision output

- Heaviest frame in the range = lowest vibration

- Designed for 24/7 operation in tough or hazardous/abrasive environments

- The right choice for factories and demanding jobs

News

All news

Feedback